Energy Code Compliance, Standards, & Practices

Today’s energy codes impact more aspects of a building and its systems than ever before. Advancements to the codes in recent years have led to a variety of technologies, materials, and processes that can be combined to achieve energy code compliance. Design professionals and engineers must apply emerging requirements, including energy modeling and system commissioning, to meet the demands of energy codes as they develop, while achieving operational and budgetary goals. This article provides solutions from knowledgeable industry professionals for the following learning objectives:

- Understand what the energy code is and why it is important to modern buildings.

- Learn about the different paths to energy code compliance and how a building can demonstrate its compliance.

- Learn why energy modeling and commissioning are becoming an integral part of the design and construction process.

Building Energy Code Fundamentals

Energy codes are part of a suite of building codes, similar to plumbing and mechanical codes, that establish minimum requirements for the materials, systems, and processes used to construct buildings, as they relate to energy use. Specifically, energy codes govern building elements that directly consume, or otherwise impact, energy.

Building energy codes are expanding to include a wider variety of systems, industries, and manufacturers. In turn, Owners and Developers can expect greater control and better management of elements that impact building energy efficiency, including HVAC, lighting, hot water usage, and building thermal envelope members, such as windows, insulation, roofs, and more. As envelope gains have been optimized for each climate zone, and as further gains are only marginal gains, controls and system operation are becoming a greater focus of the energy codes.

The International Energy Conservation Code (IECC) and the American Society of Heating, Refrigeration, and Air Conditioning Engineers (ASHRAE) are known worldwide for researching and establishing energy consumption standards for new and existing buildings. These organizations update their standards every three years, and either standard can be adopted into a jurisdiction’s building energy codes as mandatory requirements for construction projects.

Design teams, Owners, and Developers can also choose which standard to use to meet efficiency requirements, as standards from one entity may be a better fit for certain projects. For example, a multi-family high-rise building may use ASHRAE for energy-efficient building design without air-side economizers in the dwelling units. However, the IECC stipulates that if a building’s overall tonnage is above a threshold, economizers are required for a large percentage of the building.

ASHRAE Standard 90.2 is applicable to residential buildings with a maximum of three stories in height above grade. RESNET, or the Residential Energy Service Network, also has a Home Energy Rating Standard, the HERS Index, for residential dwelling units. Due to the lower adoption rate and knowledge of ASHRAE in the residential building sector, Standard 90.2 is not part of the IECC as a compliance option. Although a modified HERS Index is a compliance option known as the Energy Rating Index, ERI Method.

An engineer or design professional may also have experience meeting efficiency requirements from the IECC, while another professional may be more familiar with standards from ASHRAE. Understanding both standards and how to apply both in cost-effective manners can optimize energy while providing cost savings during construction. The choice of which standard to use for a project, however, should be based on efficiency goals and which standard will best achieve them, as neither is inherently better than the other.

One option, ASHRAE Standard 90.1, sets minimum energy-efficiency requirements for the design and construction of new buildings and of new additions to existing buildings. It also outlines how design teams and project partners can achieve compliance. Owners and Developers can reduce energy consumption in a typical building by as much as 50% with ASHRAE’s practices.

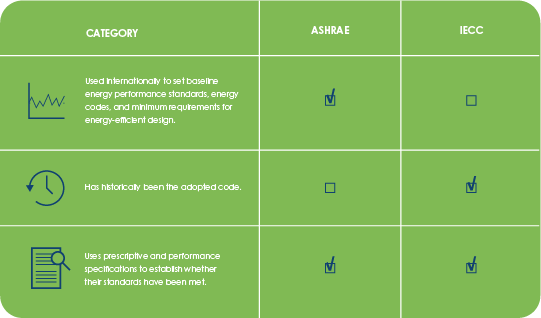

The IECC provides baseline energy-efficiency standards for the design of walls, floors, ceilings, lighting, windows, duct leakage, and more, on new projects. The standards from the International Energy Conservation Code have historically been the adopted code, while ASHRAE 90.1 is an option within the code for energy code compliance. Commonly referred to as the United States’ “model energy code,” the IECC aims to guide and inform states and local jurisdictions adopting their own building energy codes, as there is no federal code for energy efficiency. Any changes to the standards are voted on by officials from across the US, to ensure that new projects utilize the most up-to-date best practices, systems, and technologies to meet safety and efficiency thresholds.

ASHRAE and the IECC

ASHRAE Standard 90.1 (2019) and the 2021 version of the IECC make energy-efficiency practices tangible for project teams, Owners, and occupants alike, creating many opportunities to improve building energy consumption and earn energy code compliance.

The most current standards address technologies that occupants can implement and utilize themselves. These cutting-edge, yet consumer-level, technologies include smart refrigerators that conserve energy by allowing users to view the contents inside without having to open the appliance’s doors. Smart thermostats can also connect directly to utility providers. This allows the utility provider to make adjustments automatically to achieve demand control and meet electrical loads more efficiently.

Some energy-efficiency thresholds and guidelines between ASHRAE and the IECC may seem similar, but the technical calculations verifying that either standard has been met are best performed by an experienced sustainability consultant. ASHRAE Standard 90.1, for instance, is used internationally to set baseline energy performance standards, energy codes, and minimum requirements for energy-efficient building design. A building energy consumption report, providing data-driven analyses to support the results of efficiency efforts, must be included in the submission to code officials for compliance. ASHRAE’s other standards, including ASHRAE Standard 62.1, provide optimal ventilation rates to meet indoor air quality (IAQ) while providing methods for energy-efficient building design, such as strategies for demand control ventilation and adjusting ventilation rates based on occupancy schedules.

Building energy codes use prescriptive and performance specifications to establish whether their standards have been met. The IECC and ASHRAE, particularly ASHRAE Standard 62.1, both include mandatory energy-efficiency requirements, which are, as the name implies, mandatory specifications, regardless of the energy code compliance path selected. These specifications provide baselines for HVAC efficiency and building lighting controls strategy requirements that must be met by all projects.

The prescriptive energy code compliance paths for ASHRAE Standard 90.1 and the IECC set requirements for individual aspects of a project, such as building thermal envelope components, insulation material, HVAC systems, and luminaires, to promote overall efficiency. This compliance path is similar to a checklist of items that must be met to satisfy the energy code. Performance specifications use the process of energy modeling to forecast whether a building’s energy performance, while open and operating, will meet efficiency objectives for energy code compliance. Fulfilling these specifications are strategic decisions throughout a project, best made with the assistance of project partners with a keen understanding of the Owner’s or Developer’s goals.

Energy efficiency standards from ASHRAE and the IECC address a multitude of aspects pertaining to building energy consumption both directly and indirectly. Both standards represent pathways to achieving energy code compliance, but one standard might be more appropriate than the other for certain buildings. The building’s type and mechanical systems often help determine which standard will be more first-cost effective or will better support long-term energy savings. Owners and Developers who build and sell assets more regularly typically seek lower first costs and may not be keen on a high-efficiency HVAC system or other equipment with high installation costs. Alternatively, long-term asset holders may be more interested in energy-efficiency savings over a longer time horizon to offset initial investments and reduce operational and maintenance cost in the future.

However, neither standard is inherently better than the other, and both establish methods to achieve energy code compliance. Skilled project partners and licensed sustainability consultants can help Owners, Developers, and Investors ensure that the selected standard and compliance pathways achieve energy-efficiency goals and requirements.

Energy Code Compliance

In the absence of a nationwide energy code in the US, many states and local jurisdictions are implementing their own building energy codes, with the adoption and amendments to the IECC and ASHRAE Standard 90.1, to ensure that their communities are built according to the latest data-backed practices for their region.

A building energy code can be adopted by a state or local jurisdiction at any time. Regions with existing energy codes can also choose to update their building energy codes at whatever time intervals they choose. However, some officials choose to implement or update local codes after the most current standards are established, as ASHRAE and the IECC are updated every three years. Others will allow the industry to adapt to an energy code and review code adoption every six years.

The IECC often serves as a framework for jurisdictions adopting an energy code, although many local building energy codes are now more stringent than the standards set by ASHRAE, the IECC, and similar organizations, due to green building program adoptions and net zero energy initiatives. Owners and Developers in regions with efficiency requirements help reduce greenhouse gas emissions from inefficient equipment, attract and retain building tenants who highly value sustainability, as well as lower their energy-related costs.

The state of Texas, for instance, reviews and updates their building energy code every six years. Officials replaced the 2009 version of the IECC with the 2015 version during their previous review. Texas continues to follow the 2015 code while officials review the 2021 IECC, but the city of Austin, Texas, has already adopted the 2021 version for their energy code, along with other jurisdictions around the Dallas-Ft. Worth area. The state’s code becomes the minimum standard when local jurisdictions opt to surpass or change the state’s existing code. Officials in the state of Texas are currently reviewing the 2021 IECC for compliance with COMCheck and RESCheck, as well as for costs associated with the changes to the code, such as different equipment or additional testing requirements.

For example, COMCheck and RESCheck are migrating from desktop applications to web-based systems. As of March 2022, COMCheck is still awaiting updates for the 2021 IECC. Some jurisdictions still lack a firm understanding of energy codes and goals, but building energy efficiency can still be optimized and quantified by expert project partners and licensed sustainability consultants.

Updates to energy codes can also result in new methods to achieve energy code compliance. For example, envelope air barrier testing was not mandatory until the 2012 IECC for residential buildings. The energy code’s previous requirement allowed either a visual inspection or testing of the air barrier to be conducted. It was not until the 2021 IECC, when the code was updated, that air barrier testing became a requirement for commercial buildings. Now, both residential and commercial buildings require visual inspection and testing for commercial buildings, warehouses, office developments, healthcare, and more. This will pose a challenge for larger, open spaces, but building energy codes also provide updated guidance to help Owners, Developers, and project partners achieve the requirements as they develop.

Electrification, or the use of electricity as the only utility-provided energy source, is also being adopted by states and jurisdictions to combat carbon emissions. No standards exist yet for the electrification of construction sites and buildings; however, the objective of this practice is to minimize site-used fossil fuel, such as natural gas, which produces greenhouse gasses when burned. The electric grid in the US uses approximately 61% fossil fuel, 20% renewable energy, and 19% nuclear energy. It is, however, becoming cleaner, as the country increasingly avoids fossil fuel, electrifies buildings, and offsets our carbon use with other energy sources, including solar and wind from utility grid production and onsite renewable energy generation.

Energy storage, such as batteries, are being used to offset fossil fuel use and combat the instability of some renewable sources by providing energy during non-production periods. Renewable energy, including onsite renewable energy generation, is not as reliable as fossil fuels. Fuel simply needs to be set on fire to produce heat energy to spin a turbine generator. The energy from water, wind, the sun, or similar, is more dependent on the source’s immediate availability. Lithium and iron for batteries must also be mined, which destroys ecosystems, and most batteries themselves cannot be recycled. Using nuclear facilities for energy poses inherent safety concerns, as well, including core meltdowns, radioactive waste that must be securely disposed of, and the significant footprint from their construction. These and many other methods are actively researched to expand our understanding of energy use, the environment, and inspire creativity across different industries.

As the electric grid grows cleaner from non-carbon-based energy sources, buildings and systems perform more efficiently and emit less greenhouse gas. Innovation from the manufacturing and energy production industries, combined with the knowledge of sustainability engineers, allow project partners, Owners, and Developers to fulfill ambitious energy goals and decrease the environmental impact of built environments.

Energy Modeling and Commissioning

Today’s building energy codes have become more robust, due partly to the widespread availability of increasingly efficient technology and materials. This growing variety of technology and materials also underscores the different methods that can be used to achieve peak energy efficiency and code compliance.

At its most fundamental, the path to compliance with building energy codes has prescriptive and/or performance specifications. Prescriptive specifications are mandatory efficiency standards that different building energy components, such as the thermal envelope or HVAC system, must meet individually. Energy modeling, or the process of estimating a building’s anticipated energy consumption, provides the basis for performance specifications.

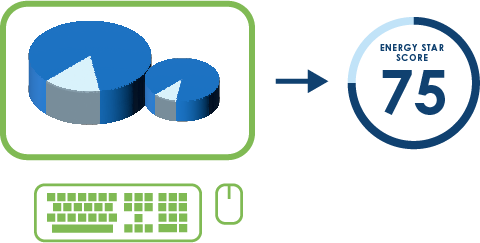

The energy modeling process uses specialized computer software to estimate a project’s expected energy consumption, by simulating how the thermal envelope, lighting, mechanical, and other connected powered systems operate and interact as a single complex system. The results are data-driven energy performance predictions that can be used to analyze how different systems or equipment could impact energy use, attract tenants, and avoid costly retrofits. Energy models can be as straightforward as calculations for a single system or as in-depth as simulations of a fully-operational building for energy code compliance.

Energy modeling is also a tool to find creative alternatives for energy-efficient building design. Project partners can leverage the results to determine which building layouts, systems, and equipment will be the most efficient before selecting or installing them. Efficiency decisions can be made proactively with energy modeling, due to the holistic perspective that the results provide for different building orientations, systems, and more. Building energy code compliance paths must be established prior to construction permitting and are required to be clearly stated on construction drawings and specifications.

The IECC and ASHRAE Standard 90.1 both identify energy modeling as an approved performance specification method to demonstrate compliance, which provides greater flexibility than many of the other options available for prescriptive energy code compliance. At the start of a project, a straightforward box model, which is calculated according to the physical properties of the schematic design ideal system, can render results based on the project’s intended shape, glazing, window distribution, or any other elements. As models progress through design, the box model is converted to a building model that takes into account actual building geometry, HVAC systems, lighting and building lighting controls, as well as hot water systems, for the development of a code-compliant energy model. In this way, energy modeling also promotes compliance with ASHRAE Standard 62.1.

Building energy modeling services are advantageous as projects progress to determine how energy consumption may be impacted by different systems or equipment. This also allows design teams to determine the best approach for energy code compliance. Modeling results also contribute to value engineering, which seeks to optimize a project’s budget by finding design alternatives that deliver comparable results with lower lifecycle costs. Together, energy modeling and value engineering allow design partners to uncover options for building capital improvements or trade-offs between different building components where costs can be significantly lowered.

Modeling earlier in the design process allows for greater insight into building energy performance much sooner, and for faster optimization of a building’s systems, in turn. Energy modeling typically begins during Schematic Design, which gives architects a more holistic picture of building systems and operating conditions. Prior to design completion, results from energy models can present options that improve building energy efficiency and that will help avoid backtracking on plans to correct inefficiencies. During this period, options for thermal envelope components and high-efficiency HVAC systems can be compared to find a cost-effective, energy-efficient design. Building energy modeling (BEM) can be utilized by sustainability experts from start to finish, enabling Architectural and MEP teams to ensure that a project’s systems will work together efficiently. The simulations, calculations, and analyses conducted for energy modeling promote efficient design choices and help ensure energy code compliance.

After a project has been built, energy code commissioning and testing can be conducted to verify that the building and installed systems operate as designed and meet or exceed the energy code requirements, as well as the Owner’s Project Requirements (OPR). Building energy codes require that an expert intermittently test, or commission, certain building equipment, the envelope, systems, lighting control, and more, to ensure that design documents are accurate. Building parameters can be updated during commissioning to meet a structure’s changing needs during its lifecycle.

For instance, heat-recovery VRV/F systems can heat and cool different parts of a building simultaneously, addressing the different needs throughout various parts of multi-family properties, office buildings, healthcare facilities, and the like. To optimize the number of air handlers for different spaces and to reduce costs, system zoning can be changed during building system commissioning. Balancing cost with controllability is possible with energy commissioning, as licensed engineers can use the results to determine which equipment and systems will decrease costs and/or increase control, according to the Owner’s or Developer’s goals.

Energy models help set an expectation for building energy use and associated costs, regardless of a building’s sector or time in operation. Energy simulations and modeling have become commonplace earlier in a project’s design process. As a result, buildings are being designed to support energy goals and to maximize opportunities for energy-efficient building design. With ongoing energy commissioning from licensed experts, buildings can operate at peak efficiency year-round, achieve energy code standards, operate efficiently throughout the life of the building, avoid fines for non-compliance, and decrease energy consumption costs.

Best Practices with Building Energy Codes

The energy codes today are continually evolving to reflect the growing number of efficient technologies, building materials, and methods available across a broader range of industries. The best practices for code compliance emphasize the planning phases and ongoing testing as primary opportunities to fulfill energy-consumption requirements and to maintain efficiency long term.

Design professionals can incorporate code-compliant designs during the Schematic Design phase to set expectations early and plan for efficiency from the start. Addressing energy-efficiency measures as early as possible decreases the margin for error, resulting in fewer inefficiencies that must be corrected later. Requirements to be solar-ready, for example, affect a building’s electrical load connected to utilities and electrical distribution systems. In such a case, roof design and high-efficiency HVAC systems are key parameters to maximize usable surface area for solar array use. Design professionals, sustainability experts, and other project partners can balance an Owner’s or Developer’s goals with energy code requirements, by combining their expertise in the art and science of integrated building design.

Prescriptive energy code compliance under the newest building energy codes, including the 2021 IECC and ASHRAE Standard 62.1, may have the greatest impact on multi-family properties, particularly in terms of ventilation. Energy recovery ventilation is now required to bring in outside air, rather than the ducts traditionally utilized in mechanical closets. An Energy Recovery Ventilator (ERV) preconditions incoming air with exhaust from the space. Additional equipment consists of ducts running through the sides of walls to the mechanical closet, where there are two fans and a heat exchanger, which are required for every dwelling unit. This may not only add to construction budgets, but it may also drive development to regions using older versions of the energy code.

However, creative designs or system alternatives that do not utilize ERVs, but fulfill the performance pathway to compliance, can be identified from the results of accurate energy modeling by sustainability experts. Energy modeling results estimate a project’s energy consumption so that project teams can determine which higher-efficiency equipment or systems can be implemented to offset less efficient aspects of a project. Box energy models can even be used to optimize a building’s general elements, such as intended window distribution, location, and orientation, from the start. Early modeling efforts, including box models, are best conducted in the Schematic Design phase to allow for proper testing and estimates. These models are often considered more straightforward, as they can be calculated according to the physical properties of a project’s proposed systems and measurements.

Once a project is built to ensure the systems operate and perform as intended, regular commissioning and testing should be performed by a licensed expert. In fact, building energy codes now require that certain equipment, systems, and the building thermal envelope be tested to ensure the accuracy of Design Documents. Best practices recommend ongoing building system commissioning to establish appropriate controls and parameters to meet the building’s needs throughout its lifecycle. The process also helps maximize the energy-efficiency of the building envelope and systems.

Building and equipment commissioning helps ensure that a structure’s systems and equipment are calibrated to their optimized ranges. In turn, buildings can operate at peak performance, while decreasing their energy consumption costs and achieving energy code compliance.

Closing

Achieving energy code compliance for modern buildings involves more elements of building design, system controls, and equipment than ever. Knowledgeable design professionals and engineers can utilize cutting-edge technologies and emergent processes, such as energy modeling and commissioning, to meet the demands of building energy codes and of operational goals. Understanding the energy codes and implementing their best practices allows design teams to maintain a project’s budget, while creating opportunities to decrease energy costs from start to finish.

Download Guide

Learn more about Energy Code Compliance, Standards, & Practices by downloading our guide.

Leave a Reply

Want to join the discussion?Feel free to contribute!