Design Implications: US Department of Energy’s New Efficiency Requirements in 2023

The U.S. Department of Energy (DOE) will enact new nationwide efficiency requirements for HVAC equipment on January 1, 2023. As part of the DOE’s goal to reduce overall energy consumption, the rating procedure (i.e., the performance calculation) has become more stringent and complex. Excluding split system heat pumps, split system air conditioners that do not meet these new ratings will not be installable after January 1, 2023. Equipment currently in production is being phased out in anticipation of this new mandate, some as early as the end of August 2022. Although there will be different ratings per region, updated equipment should be reviewed and incorporated into all project designs immediately. As HVAC engineering experts who work closely with HVAC equipment manufacturers, we take pride in being at the forefront of what the DOE mandates mean to our industry and how these changes will affect the project design and the owner’s pocketbook. In order to prepare our clients and peers for this update, in this article, our team will provide:

- At-A-Glance Overview of DOE updates

- Design Implications of Updates

- Expectations for Owners & JSE’s Preparation Plan

Overview of Efficiency Requirement Updates

DOE Region Map & Minimum Efficiency Requirements for 2023

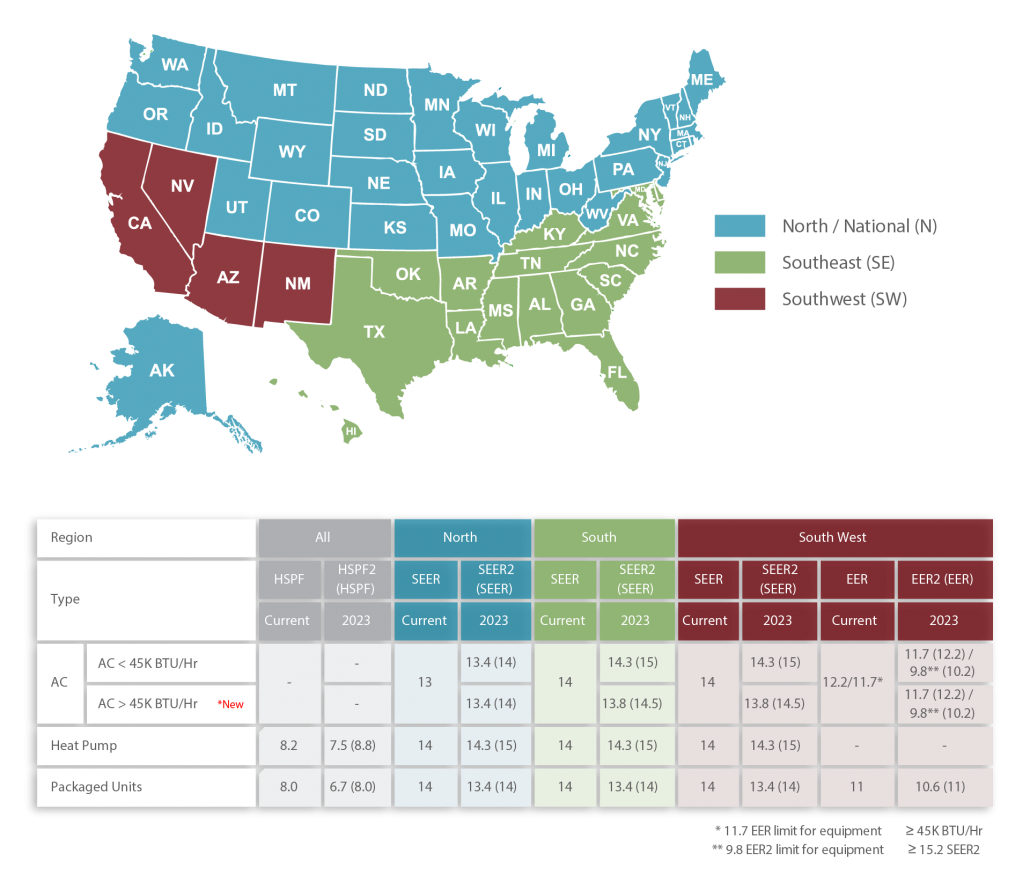

SEER (Seasonal Energy Efficiency Ratio) has been the efficiency ratio for residential AC equipment, sized at 5 tons of cooling and below, for the past 25 years. There have been considerable increases in the SEER rating requirements and efficiency standards throughout that time. For example, in 2007, our industry moved from SEER 10 to SEER 13, and again in 2015 from SEER 13 to 14. In this latest update, The Department of Energy decided that parts of the criteria used to model the SEER rating needed modification to reflect more realistic scenarios. Due to this change in criteria, the nomenclature of the efficiency ratio was updated as well to SEER2. This upgrade has increased a variety of rating benchmarks for HVAC equipment.

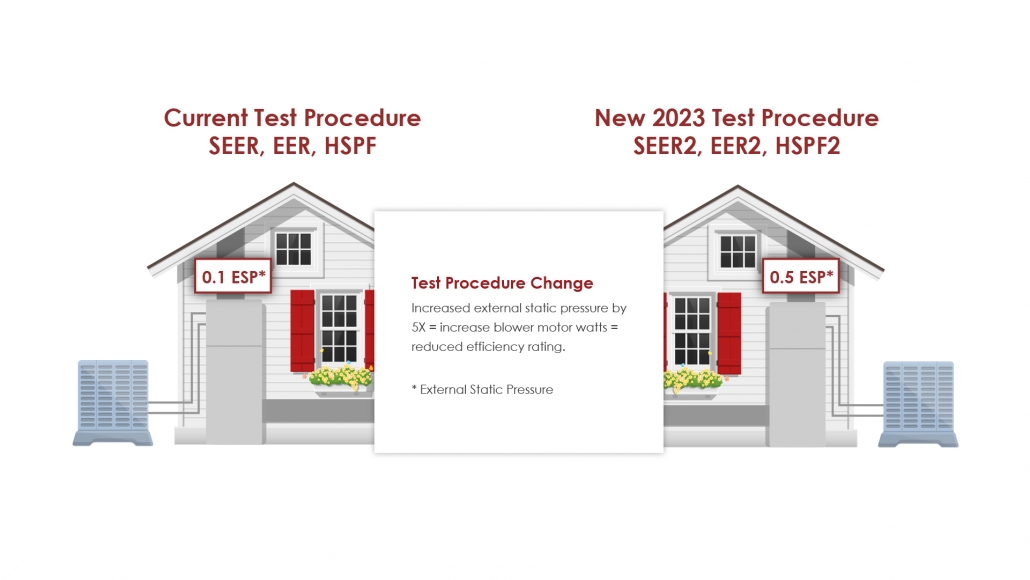

- Significantly, the external static pressure (ESP) required by the indoor unit (air handler, fan coil) is being raised from 0.1″ to 0.5″. We know that this significant increase in static pressure produced will increase the horsepower required, but we do not believe it will increase the physical size of the air handler cabinet.

- Although not a specific mandate, manufacturers have found an easy way to boost efficiency by adding a Thermal Expansion Valve (TXV). Through the testing process, manufacturers have found that a TXV can save significant compressor energy by more precisely metering and distributing refrigerant to the evaporator coil. In most cases, the TXV will now be factory mounted in the Air Handler.

- Other metrics are affected by this mandate, including Heating Seasonal Performance Factor (HSPF) updating to HSPF2 for heat pumps and Energy Efficiency Ratio (EER) updating to EER2 for equipment applied to the southwest region of the US. Heat pumps that are currently in production will be allowed to be installed next year, but equipment manufactured after January 1, 2023, must meet the new HSPF2 metric of 8.8. It should be noted that manufacturers are focusing on split system air conditioner designs and ratings and will follow up with heat pump designs and ratings thereafter.

- To achieve these higher efficiency requirements, we expect to see a shift from PSC motors to more efficient ECM motors and other newer technologies incorporated.

These changes in multiple rating benchmarks will result in design implications.

Design Implications

Test Procedure Comparison

Approximately 70% of current products in the base tier of HVAC equipment will not meet the 2023 minimum efficiency requirement. All current products will need to be re-tested and re-rated using the new criteria to account for modifications and design revisions. However, we are learning that manufacturers are redesigning to enhance their equipment’s features and efficiency. It is important to note that increasing efficiency means equipment sizing is affected.

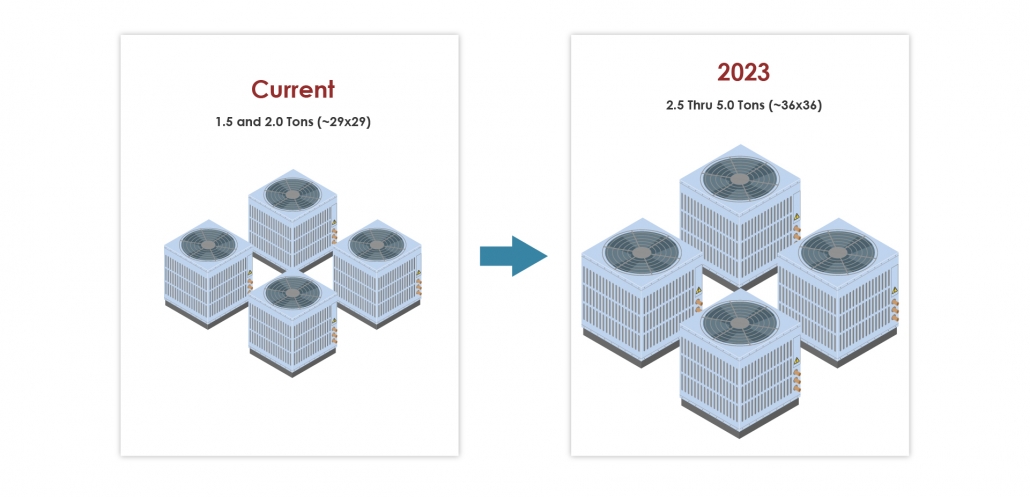

- Outdoor split system AC equipment will require more surface area (larger coils), thereby increasing the cabinet size. Preliminary information indicates that 2.5- and 3-ton sizes are increasing to an approximate 36×36 footprint. While smaller capacities will have approximately the same footprint, they may increase in height.

- Any designs where Developers are using horizontal (pancake) air handling units may be at risk, especially for heat pumps. Jordan & Skala Engineers encourages design professionals to gather information from manufacturers about whether that system will meet the new criteria. If a pancake unit does not meet the new requirements, a move to vertical air handling may be necessary and could affect architectural floorplans and rentable square footage.

As of July 2022, manufacturers are still testing and rating equipment performance and specs, making it difficult, although still necessary, for design professionals to incorporate SEER2-rated equipment into designs.

Outdoor Unit Sizes Are Changing

Expectations for Owners & JSE’s Preparation Plan

While waiting for finalized manufacturers’ data, Jordan & Skala Engineers plans to immediately specify more energy-efficient equipment into our designs. We also intend to focus on client education to support mandate compliance and reduce revisions during design installation. We encourage our clients to expect revisions as new data is received and continue ongoing conversations with project Contractors regarding imported equipment status, supply chain logistics, and re-rating and re-testing protocol.

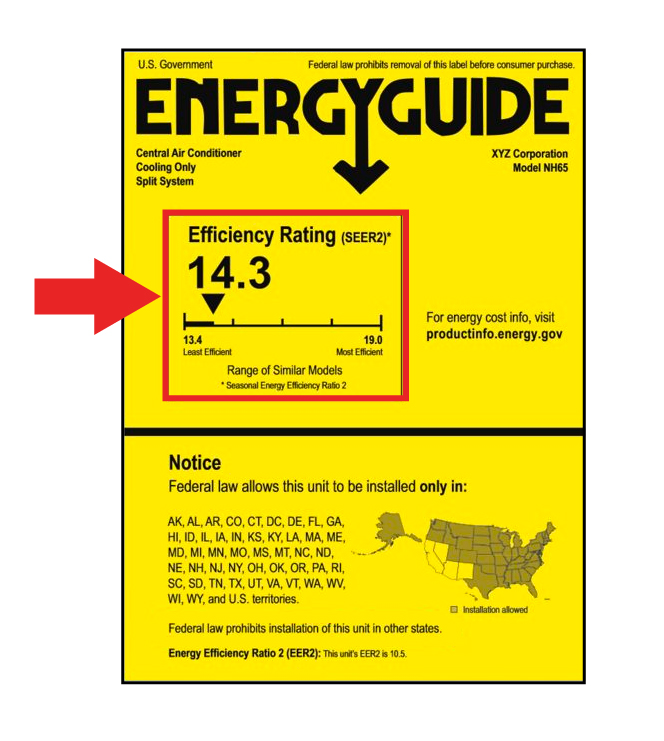

2023 Compliant EnergyGuide Label

Jordan & Skala’s team of expert HVAC engineers is well-prepared to proceed with design updates and consult our clients through this mandate. Contact our team with any questions.

Leave a Reply

Want to join the discussion?Feel free to contribute!